If you’ve ever wondered about the inner workings of a diesel engine and how it differs from a gasoline engine, one of the most commonly asked questions is: Does a diesel engine have spark plugs?

If you have the same question in your mind, let’s clear the doubt in this detailed article. Some vehicle owners who handle their own minor repairs, like using best paintless dent repair tools, often get curious about deeper engine systems too.

Does a Diesel Engine Have Spark Plugs?

Unlike gasoline engines, diesel engines do not use spark plugs. Diesel engines rely on a compression ignition system, which means the air inside the engine is compressed to such high pressures that it heats up and ignites the diesel fuel.

Key Takeaways

- Diesel engines rely on compression to ignite the fuel, rather than using spark plugs as in gasoline engines.

- Diesel engines use high compression ratios to raise the temperature inside the cylinders to ignite the fuel.

- Diesel fuel is more energy-dense than gasoline, allowing for this different method of ignition.

How Diesel Engines Work

Compression Ignition vs. Spark Ignition

Unlike gasoline engines, which use spark plugs to ignite the air-fuel mixture, diesel engines rely on compression ignition.

This means that instead of using a spark plug to create a spark that ignites the fuel, diesel engines increase the pressure inside the cylinders. The air is compressed to such a high level that it heats up to the point where it ignites the injected diesel fuel.

This process is much more efficient for diesel engines, as it allows them to generate more power and use fuel more efficiently.

The high compression ratios also help explain why diesel engines are known for their torque and fuel efficiency.

How Diesel Fuel Ignites

When you start a diesel engine, air is drawn into the combustion chamber. The air is compressed by the piston, raising its temperature and pressure. Once the air is hot enough, the fuel (diesel) is injected directly into the combustion chamber.

The heat from the compressed air is enough to ignite the fuel without the need for a spark. This process is often referred to as “compression ignition,” which is the key differentiator between gasoline engines and diesel engines.

In contrast, gasoline engines use spark plugs to ignite the air-fuel mixture. The spark plug generates a spark at the right moment, causing the mixture to combust.

Diesel engines don’t require this ignition method due to the unique properties of diesel fuel and the higher temperatures created by the compression process.

Why Don’t Diesel Engines Use Spark Plugs?

Different Combustion Process

The primary reason diesel engines do not use spark plugs is because of the way they ignite fuel. As mentioned, diesel engines rely on compression to raise the temperature of the air within the cylinder to a point where the diesel fuel spontaneously ignites.

The high compression ratios in diesel engines make this process efficient without needing a spark.

On the other hand, gasoline engines operate at much lower compression ratios, meaning they need a spark to ignite the air-fuel mixture. Gasoline engines rely on spark plugs because the mixture of air and fuel is not hot enough to ignite by compression alone.

Fuel Differences

Diesel fuel is more energy-dense and has a higher flashpoint compared to gasoline, which is another reason diesel engines don’t need spark plugs.

Diesel requires higher compression to reach the necessary temperature for combustion, whereas gasoline is designed to ignite at lower temperatures with the help of a spark.

Durability and Efficiency

The absence of spark plugs in diesel engines contributes to their durability and efficiency. Diesel engines are built to handle higher pressures, and the lack of spark plugs reduces the need for frequent maintenance or replacements of ignition components. This also eliminates concerns commonly associated with gasoline engines, such as how often ignition coil replacement is needed or replacing spark plugs.

This is one of the reasons why diesel engines tend to last longer than gasoline engines and are more suitable for heavy-duty applications like trucks, buses, and industrial machinery.

The Role of Other Components in Diesel Engines

Diesel engines are known for their power and fuel efficiency, making them the preferred choice for heavy-duty vehicles and machinery.

Unlike gasoline engines, which rely on spark plugs to ignite the fuel, diesel engines have a unique set of components that work together to ensure efficient operation and long-term durability. Below are some of the critical components in a diesel engine and their roles.

Glow Plugs

Glow plugs are essential components in diesel engines, especially for starting the engine in cold conditions.

Since diesel engines don’t use spark plugs, they rely on glow plugs to heat the air inside the engine’s cylinders, making it easier for the diesel fuel to ignite. Glow plugs are electrical heating elements that warm the combustion chamber before the engine starts.

Unlike spark plugs, which fire during the engine’s operation, glow plugs only function during the startup phase.

As the engine warms up, the glow plugs turn off, and they do not contribute to the combustion process once the engine is running. This is particularly crucial in cold weather, where glow plugs ensure that the diesel fuel can ignite properly despite the cold temperatures.

I have written a dedicated post that explains what do glow plugs do in a diesel engine. You must check that out If you are interested to learn about it.

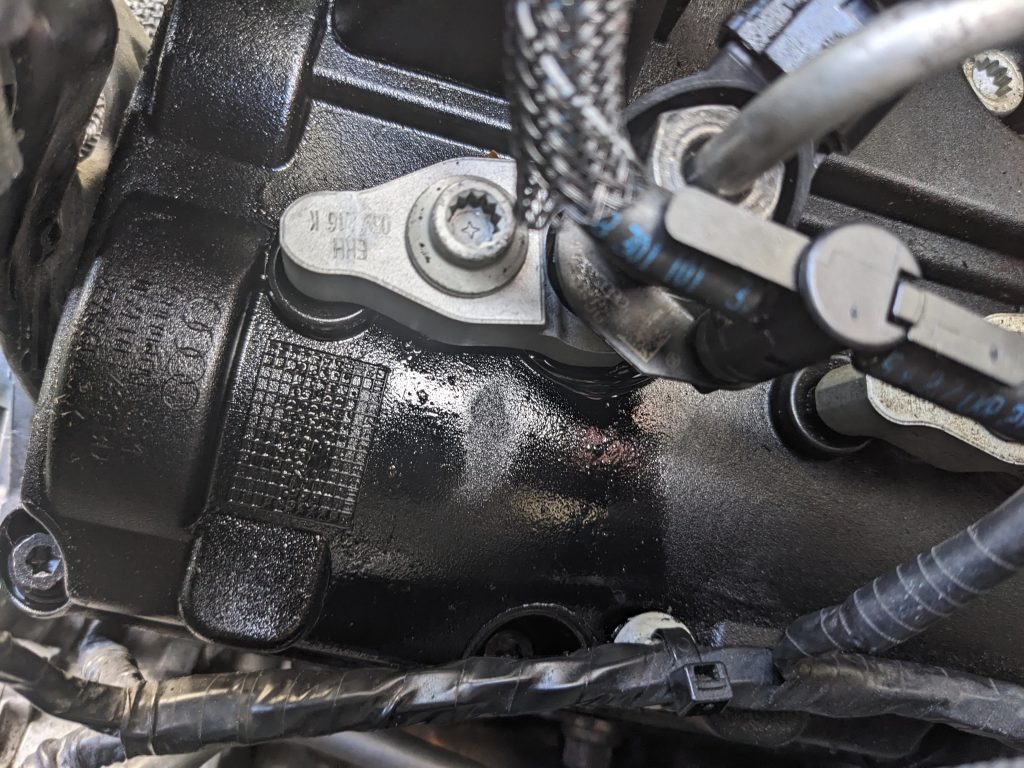

Fuel Injectors

In diesel engines, fuel injectors play a pivotal role in delivering fuel directly into the combustion chamber at very high pressure.

The injectors atomize the diesel fuel into a fine mist, ensuring that it mixes evenly with the air inside the chamber. This mixture ignites when it comes into contact with the highly compressed air, initiating the combustion process.

Fuel injectors are incredibly important for ensuring that the engine runs efficiently. They help control the amount of fuel injected into the cylinders, which directly impacts fuel efficiency, performance, and emissions.

Over time, dirty or worn injectors can lead to poor fuel atomization, reducing engine performance and increasing fuel consumption. Regular maintenance, including cleaning or replacing fuel injectors, is essential to keep the diesel engine running at its best.

Turbochargers and Intercoolers

To boost engine performance and efficiency, many diesel engines are equipped with turbochargers and intercoolers.

A turbocharger is a device that compresses the air entering the engine, which allows for more air and fuel to be burned during combustion. This increased air volume leads to greater power output and more efficient fuel consumption.

However, compressing air also increases its temperature, which can reduce its density and affect combustion.

This is where the intercooler comes in. The intercooler cools the compressed air before it enters the combustion chamber. By lowering the temperature of the air, the intercooler increases its density, allowing for more efficient combustion and preventing the engine from knocking.

The combination of turbochargers and intercoolers has become essential in modern diesel engines, helping them to achieve higher power outputs while maintaining fuel efficiency and reducing the risk of engine damage due to high temperatures.

Diesel vs Gasoline Engines: Key Differences

Although diesel and gasoline engines both serve the purpose of converting fuel into mechanical energy to power vehicles, they operate differently. Understanding these differences can help clarify why diesel engines are often preferred for heavy-duty applications.

Compression Ratio

One of the most significant differences between diesel and gasoline engines is the compression ratio.

Diesel engines typically have a higher compression ratio than gasoline engines. This means that the air inside a diesel engine is compressed to a much higher pressure before fuel is injected.

The compression ratios in diesel engines range from 14:1 to 25:1, while gasoline engines typically operate at compression ratios of 8:1 to 12:1.

The higher compression ratio in diesel engines allows them to generate more power per unit of fuel and makes them more fuel-efficient.

This is one of the main reasons why diesel engines are preferred in trucks, buses, and other heavy-duty machinery that need to operate efficiently over long distances.

Fuel Efficiency

Diesel engines are renowned for their fuel efficiency. Diesel fuel contains more energy per gallon than gasoline, which allows diesel engines to travel further on the same amount of fuel.

This is a major advantage for long-distance drivers and commercial vehicles that need to cover large distances without frequent refueling.

In fact, diesel engines typically achieve 20-30% better fuel efficiency than gasoline engines. This makes diesel engines the ideal choice for long-haul transportation, where maximizing fuel economy is a priority.

Power and Torque

Diesel engines produce more torque than gasoline engines, which is why they are better suited for heavy-duty applications.

Torque is the force that moves a vehicle from a standstill, and diesel engines excel at producing high amounts of torque at low revolutions per minute (RPMs). This characteristic makes diesel engines ideal for towing, hauling, and powering large vehicles like trucks and buses.

While gasoline engines may produce more horsepower at high RPMs, diesel engines produce superior torque, which is essential for vehicles that need to move heavy loads or work in tough conditions.

Emissions

While diesel engines offer better fuel efficiency and torque, they are generally known for producing higher levels of particulate matter (PM) and nitrogen oxides (NOx) compared to gasoline engines.

These emissions can contribute to air pollution and are a concern for environmental regulations.

However, advancements in diesel technology, such as the introduction of particulate filters and selective catalytic reduction (SCR) systems, have significantly reduced these harmful emissions in recent years.

Modern diesel engines are much cleaner than their predecessors and meet stricter emission standards, making them more environmentally friendly.

Diesel engines also use fuel injectors to spray diesel into the combustion chamber, where it ignites due to the high compression.

This process makes diesel engines more fuel-efficient and capable of producing greater torque, which is why they are used in trucks, buses, and other heavy-duty vehicles. Diesel engines are built to handle higher compression levels, which is why spark plugs aren’t necessary.

If you’ve ever wondered about the inner workings of a diesel engine and why it doesn’t need spark plugs, now you know that it’s all due to the efficiency of compression ignition.

If you need some help with a Ford diesel engine, a diesel vehicle, or a diesel engine repair in specific, we at URBS Garage offer such services to help those who may need it.

Frequently Asked Questions

1. Can you put spark plugs in a diesel engine?

No, diesel engines don’t require spark plugs because they use compression ignition instead of spark ignition.

2. How does a diesel engine start without spark plugs?

Diesel engines use glow plugs to heat the air in the cylinders during startup, helping ignite the diesel fuel without needing spark plugs.

3. What’s the difference between diesel and gasoline engines?

Diesel engines operate at higher compression ratios, are more fuel-efficient, and produce more torque than gasoline engines. They also don’t require spark plugs, unlike gasoline engines.

Conclusion

In conclusion, diesel engines do not use spark plugs because of their reliance on compression ignition rather than spark ignition.

Diesel fuel’s higher energy density and the engine’s higher compression ratios make it possible for the engine to ignite the fuel without a spark. Instead, diesel engines use glow plugs to help start the engine in cold weather and rely on fuel injectors for efficient fuel delivery.

While diesel engines are more fuel-efficient, and durable, and produce more torque than gasoline engines, they require different maintenance procedures and components.

Understanding how a diesel engine works—and why spark plugs aren’t needed—can help you better appreciate the technology behind these powerful and efficient machines.

While diesel engines do use glow plugs to help with starting the engine, these serve a different purpose—they heat the air for ignition during cold weather, not during normal engine operation.