When you hear the word “diesel,” you probably think of large trucks, buses, or industrial machines, and it’s no surprise. Many vehicle owners searching for a reliable diesel repair shop near me monfort heights rely on diesel-powered systems for their durability and performance.

Diesel engines are commonly used in these vehicles due to their fuel efficiency, reliability, and high torque, especially when comparing long-term operating costs and diesel vs gas prices.

How Does a Diesel Engine Work?

A diesel engine works by compressing air to high pressure and temperature, then injecting fuel that ignites due to the heat. This creates power for the vehicle, making it efficient and reliable for heavy-duty tasks. This entire process also plays a role in many automotive troubleshooting Burlington KY situations involving diesel performance, often handled by a trusted diesel engine repair service monfort heights.

Key Takeaways:

- Diesel engines compress air to high pressure and temperature before injecting fuel.

- Diesel engines are more efficient, producing more torque and better fuel economy.

- Diesel engines power trucks, buses, and machinery, offering durability and strength.

What Makes a Diesel Engine Different From a Gasoline Engine?

While both diesel and gasoline engines are internal combustion engines, they operate differently. The key differences lie in the way fuel is ignited and the fuel types used:

Gasoline engines use a spark plug to ignite the air-fuel mixture.

Diesel engines do not use spark plugs. Instead, they rely on compression to ignite the fuel.

This difference in ignition methods leads to variations in engine design and performance, which we’ll explore in more detail below.

How a Diesel Engine Works: The Basic Process

The fundamental process in a diesel engine involves four stages, known as the four-stroke cycle.

These stages are intake, compression, power, and exhaust. Here’s a breakdown of each stage:

Intake Stroke

The intake stroke begins when the intake valve opens, and the piston moves downward. During this stroke, air is drawn into the cylinder from the outside through the intake valve.

Unlike gasoline engines, diesel engines only draw in air during the intake stroke, with fuel added later during compression.

Compression Stroke

Once the intake valve closes, the piston moves upward to compress the air in the cylinder.

Diesel engines are designed with a high compression ratio, meaning that the air is compressed to a much smaller volume, which increases the pressure and temperature.

The compression ratio in a diesel engine is typically around 14:1 to 25:1, compared to 8:1 to 12:1 in gasoline engines.

Power Stroke (Fuel Injection and Ignition)

As the air reaches a high temperature (often exceeding 1,000°F), the fuel injector sprays a fine mist of diesel fuel into the hot, compressed air.

Because the air is so hot, the fuel ignites instantly without the need for a spark plug.

The combustion of the fuel creates a rapid expansion of gases, which pushes the piston down and turns the crankshaft, generating power for the engine.

Exhaust Stroke

After the power stroke, the exhaust valve opens, and the piston moves upward again.

This pushes the exhaust gases from the combustion process out of the cylinder and into the exhaust system. If there’s a fault in the flow, professional exhaust system repair in Burlington, KY, can help restore it. Then, the cycle repeats.

Key Components of a Diesel Engine

Diesel engines contain several key components that are critical to their operation. Let’s take a look at these essential parts:

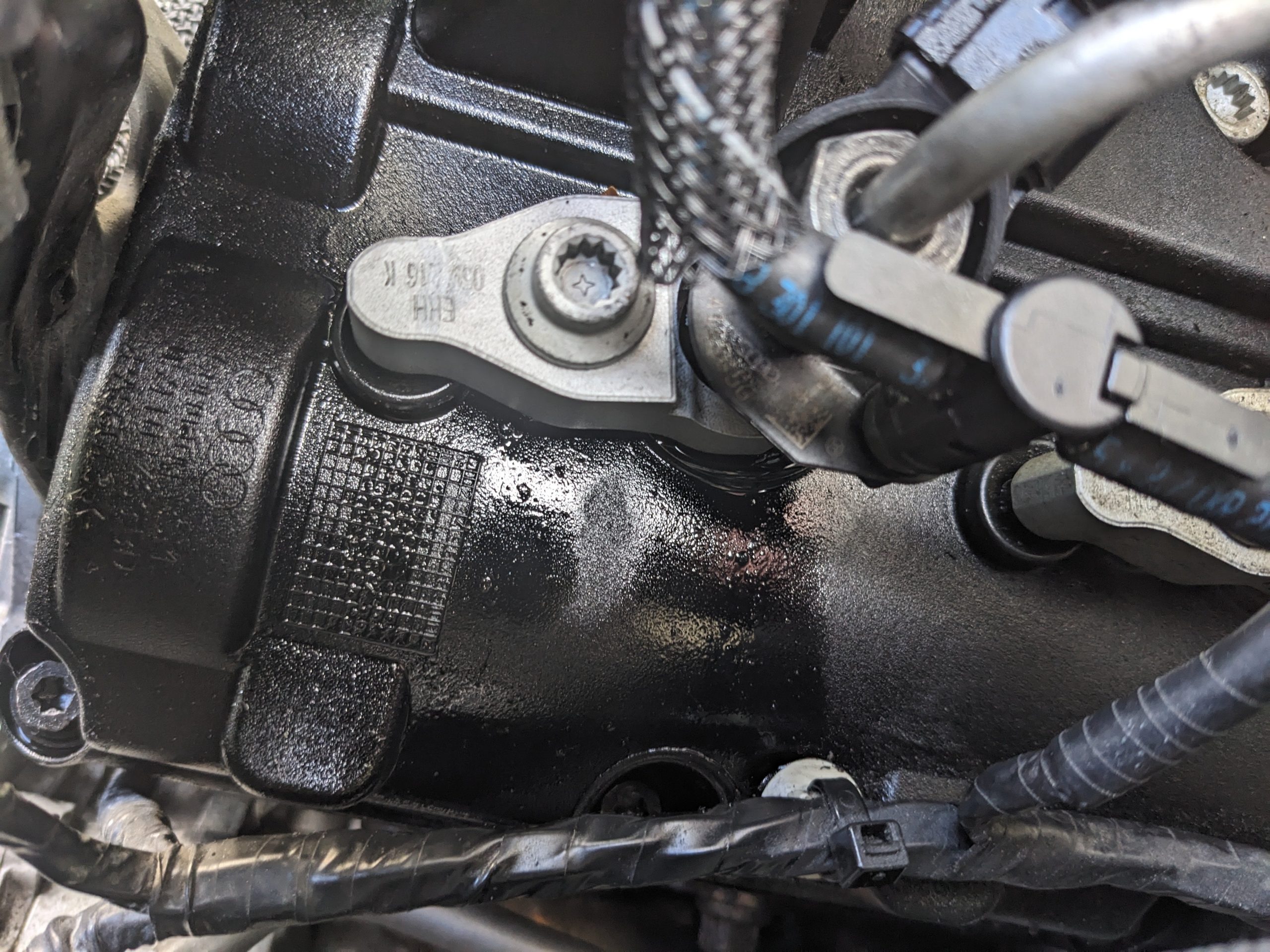

1. Fuel Injectors

Fuel injectors are responsible for injecting the precise amount of fuel into the combustion chamber.

In a diesel engine, the fuel injectors spray a fine mist of diesel fuel into the high-pressure air during the compression stroke, causing ignition.

2. Compression Chamber

The compression chamber is where the air is compressed to a high pressure. The high compression ratio is what makes diesel engines more efficient than gasoline engines.

The high temperature resulting from this compression causes the fuel to ignite spontaneously when injected.

3. Turbocharger

Many diesel engines use a turbocharger to improve efficiency and performance.

A turbocharger uses exhaust gases to spin a turbine, which forces more air into the engine, increasing the amount of oxygen available for combustion. This results in more power and greater fuel efficiency.

4. Intercooler

An intercooler helps lower the temperature of the compressed air before it enters the engine.

Lowering the air temperature increases its density, allowing the engine to burn more fuel and produce more power.

5. Exhaust Gas Recirculation (EGR) Valve

The EGR valve recirculates a portion of the exhaust gases back into the engine to reduce nitrogen oxide (NOx) emissions. This helps meet environmental standards and improve engine efficiency.

Advantages of Diesel Engines

Diesel engines offer several advantages over gasoline engines, making them a popular choice for various types of vehicles and machinery:

1. Fuel Efficiency

Diesel engines are generally more fuel-efficient than gasoline engines. This is because diesel fuel contains more energy per gallon than gasoline, and the high compression ratio in diesel engines allows for better energy extraction from the fuel.

As a result, diesel engines tend to provide better fuel economy and longer range for trucks, buses, and other large vehicles.

2. More Torque

Diesel engines are known for producing more torque than gasoline engines. This is due to the higher compression ratios and the energy density of diesel fuel.

The increased torque makes diesel engines ideal for heavy-duty applications, such as hauling large loads in trucks or powering industrial machinery.

3. Durability and Longevity

Diesel engines are built to withstand higher levels of stress due to their high compression ratios. As a result, they tend to last longer than gasoline engines.

Diesel engines are often found in vehicles and machinery that require long operational lifespans, such as commercial trucks, buses, and construction equipment.

4. Better for Heavy-Duty Work

Due to the greater torque and fuel efficiency, diesel engines are more suited for heavy-duty work.

Trucks, buses, and large equipment benefit from diesel engines, which can handle more substantial workloads without compromising performance.

Whenever you face any issue with your diesel vehicle, just visit our shop, URBS Garage and we’ll help you out. We offer diesel repair services in Finneytown for various brands including Ford, supported by an experienced heavy diesel mechanic who understands complex engine systems. We also support performance improvements such as ECU tuning when appropriate for diesel efficiency and drivability.

Apart from that, we offer our service of diesel engine repair in Finneytown to take care of this in specific.

Common Applications of Diesel Engines

Diesel engines are found in a wide range of vehicles and equipment. Some common applications include:

1. Trucks and Commercial Vehicles

Diesel engines power most large trucks and commercial vehicles due to their ability to produce high torque and excellent fuel efficiency.

Whether it’s for long-haul trucking or local delivery, diesel engines offer the durability and power needed for transporting goods.

2. Buses and Public Transportation

Many buses and public transportation vehicles use diesel engines for similar reasons—fuel efficiency and durability. Diesel-powered buses can travel longer distances on a single tank of fuel, making them ideal for city routes and long-distance travel.

3. Construction and Agricultural Machinery

Heavy machinery such as bulldozers, tractors, and excavators rely on diesel engines to handle large, demanding tasks.

Diesel’s ability to provide substantial torque and operate under heavy loads makes it ideal for construction and agricultural applications.

4. Marine Engines

Diesel engines are also commonly used in marine applications, including ships, boats, and submarines.

Diesel’s efficiency and reliability make it an excellent choice for marine vessels that need long operational hours and durability.

The Environmental Impact of Diesel Engines

While diesel engines are more fuel-efficient and provide more power than gasoline engines, they also have some environmental downsides.

Diesel engines tend to produce higher amounts of nitrogen oxides (NOx) and particulate matter (PM), which are harmful pollutants.

Diesel Emissions

Diesel emissions, particularly NOx and particulate matter, can contribute to air pollution and have adverse health effects.

To address these concerns, modern diesel engines are equipped with technologies like the Exhaust Gas Recirculation (EGR) valve and diesel particulate filters (DPF) to reduce emissions.

The Shift Toward Cleaner Technologies

In recent years, diesel engines have faced increased scrutiny due to environmental concerns.

However, manufacturers have made significant strides in improving diesel technology, such as the introduction of clean diesel technology, which reduces emissions while maintaining the benefits of fuel efficiency and power.

Frequently Asked Questions

1. How does a diesel engine differ from a gasoline engine?

The main difference is that diesel engines rely on compression to ignite the fuel, while gasoline engines use spark plugs. Diesel engines are more fuel-efficient and produce more torque than gasoline engines.

2. What are the advantages of diesel engines?

Diesel engines offer greater fuel efficiency, more torque, and better durability than gasoline engines. They are ideal for heavy-duty vehicles and machinery.

3. Are diesel engines environmentally friendly?

While diesel engines are more fuel-efficient, they tend to produce higher emissions of nitrogen oxides (NOx) and particulate matter. However, modern diesel engines are equipped with technologies to reduce these harmful emissions.

Conclusion

Diesel engines have been powering vehicles and machinery for over a century, and they continue to be a crucial part of the automotive and industrial sectors.

With their fuel efficiency, torque, and durability, diesel engines are the ideal choice for heavy-duty applications like trucks, buses, and construction equipment.

While diesel engines have environmental impacts, advancements in technology continue to make them cleaner and more efficient. Understanding how a diesel engine works helps to appreciate its role in modern society, from transportation to industry.